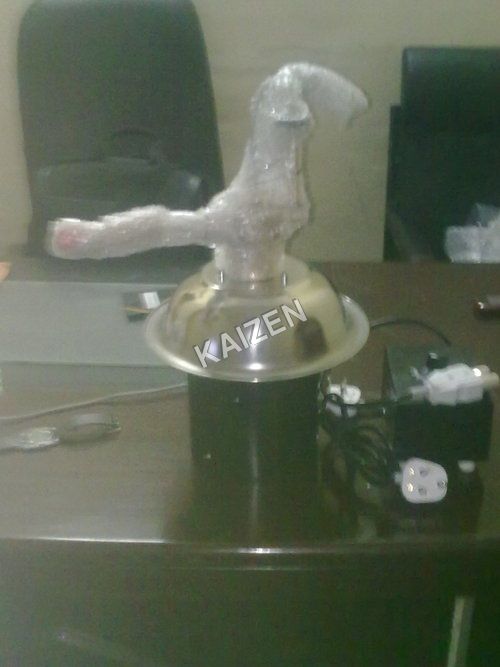

Cloud & Pour Point Apparatus

Product Details:

- Specimen Size Typically 50 ml (as per ASTM D97/D2500)

- Equipment Type Cloud & Pour Point Apparatus

- Mounting Type Bench-top

- Humidity Ambient

- Operating Voltage 230 V AC

- Features Double walled insulated body, easy maintenance, corrosion-resistant finish, removable test jar, conforms to ASTM D2500/D97

- Resolution 0.1C

- Click to View more

X

Cloud & Pour Point Apparatus Price And Quantity

- Heat-resistant glass

- Stainless steel inner chamber with powder-coated outer body

- 50-100 ml as per method

- 10°C to 38°C, non-condensing

- Glass wool insulation for optimal cold retention

- Test jar, thermometer, stirrer, bath assembly, insulated top cover

- Approx. 45 x 30 x 40 cm

- Solid CO2/isopropyl alcohol or ice/salt as per required temperature range

Cloud & Pour Point Apparatus Product Specifications

- 50 Hz

- Determining cloud point and pour point of petroleum products

- 0.1C

- Manual

- 230 V AC, 50 Hz

- Analog thermometer

- Manual operation

- Typically 50 ml (as per ASTM D97/D2500)

- Double walled insulated body, easy maintenance, corrosion-resistant finish, removable test jar, conforms to ASTM D2500/D97

- 230 V AC

- Bench-top

- Approx. 5 kg

- Ambient

- Cloud & Pour Point Apparatus

- 0.5C

- Cloud Point & Pour Point determination as per test standards

- Laboratory analysis of petroleum products

- Approx. 40 cm

- Standard test jar opening

- Up to -40C

- Manual

- One test sample

- 1 at a time

- Immediate

- -40C to +50C

- Heat-resistant glass

- Stainless steel inner chamber with powder-coated outer body

- 50-100 ml as per method

- 10°C to 38°C, non-condensing

- Glass wool insulation for optimal cold retention

- Test jar, thermometer, stirrer, bath assembly, insulated top cover

- Approx. 45 x 30 x 40 cm

- Solid CO2/isopropyl alcohol or ice/salt as per required temperature range

Cloud & Pour Point Apparatus Trade Information

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Africa, Western Europe, Central America, Eastern Europe, Australia, Middle East, South America, Asia, North America

- ISO Certification, MSME Certificate

Product Description

We are established as one of the prominent manufacturers and exporters of Cloud & Pour Point Apparatus. All these apparatuses are assembled with various cooling bath that are sturdily made by using high quality materials. These apparatuses are extensively used for measuring the cloud and pour rate of jet fuel, diesel fuel and finished lubricants. Further, we make available the array of Cloud & Pour Point Apparatus units to our clients at competitive prices.

Features:

- Easy moving caster wheels

- Provide accurate measurements

- Longer service life

Further Details:

This is made according to specification laid by IP 15 & IS 1448 (P :

10) 1970. The pour point is lowest temperature at which the oil will just fail to flow. The cloud and pour point apparatus is a laboratory instrument which is used to perform several test on oil, thus, finds wide application in petroleum industry. Made out of supreme quality steel, this apparatus in equipped with single & double stage refrigeration system for performing test on varied temperatures.A Glass jar for containing oils, Jacket, disc and gasket as specified are also provided.

- Cloud & Pour Single with Insulated Body.

- Cloud & Pour Point Two Test with Insulated Body.

- Cloud & Pour Point Four Test with Insulated Body.

- Cloud & Pour Point Six Test with Insulated Body.

- Cloud Pour Point App. WITH REFRIGERATION SYSTEM (for 2 test App.) Temp. upto -30 degree C.

Precise Measurement and Build Quality

Engineered for reliability, the apparatus features a double-walled insulated body, utilizing glass wool for optimal cold retention. The stainless steel inner chamber ensures corrosion resistance, while the powder-coated outer body enhances durability and longevity, making the equipment suitable for routine laboratory use.

Flexible Cooling and Accurate Determination

The system accommodates solid CO2/isopropyl alcohol or ice/salt as cooling media, enabling users to achieve required temperature ranges for various test standards. The heat-resistant glass test jar and analog thermometer deliver accurate measurements with a resolution of 0.1C and 0.5C accuracy, supporting cloud and pour point testing down to -40C.

User-Friendly Design and Laboratory Application

All essential accessoriestest jar, thermometer, stirrer, bath assembly, and insulated top coverare included, simplifying setup and operation. Manual controls allow precise intervention during tests, while the apparatus remains easy to maintain and operate, perfectly suited for bench-top laboratory analysis of petroleum products.

FAQs of Cloud & Pour Point Apparatus:

Q: How is the Cloud & Pour Point Apparatus used to determine the cloud and pour points of petroleum products?

A: The apparatus facilitates cloud and pour point testing by cooling a petroleum sample in a heat-resistant glass jar using specific media (solid CO2/isopropyl alcohol or ice/salt). The operator manually observes the samples behavior and records the temperature at each transition, following ASTM D97/D2500 standards.Q: What materials ensure durability and optimal cold retention in the apparatus construction?

A: The inner chamber is crafted from stainless steel, offering excellent corrosion resistance, while the powder-coated outer body adds durability. Glass wool insulation enhances cold retention, maintaining stability during low-temperature measurements.Q: When should this apparatus be used in laboratory settings?

A: This equipment is ideal for routine analysis, quality control, and research of petroleum products in laboratories, whenever it is necessary to accurately determine cloud and pour points as per ASTM methods.Q: Where can the Cloud & Pour Point Apparatus be placed for operation?

A: Designed for bench-top mounting, the apparatus can be placed in any laboratory space with ambient operating conditions between 10C and 38C and access to a standard 230 V AC, 50 Hz power supply.Q: What is the process of setting up and operating the apparatus manually?

A: After placing the sample in the test jar and assembling all supplied accessories, select the appropriate cooling media. Manually stir the sample and monitor the temperature via the analog thermometer, recording readings at cloud and pour points.Q: What are the benefits of using this apparatus for petroleum product analysis?

A: Users benefit from high measurement accuracy (0.5C), immediate analog response, corrosion-resistant components, easy maintenance, and flexibility in cooling options. It ensures compliance with global ASTM standards, delivering reliable test results for both manufacturers and exporters.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Oil & Petroleum Testing Instruments' category

|

KAIZEN IMPERIAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |